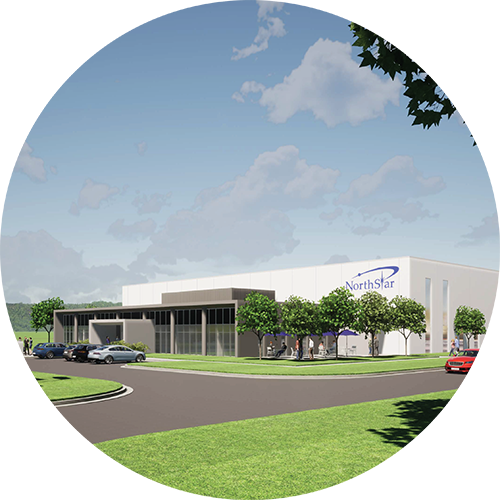

NorthStar's

Manufacturing

We routinely produce Copper-67 (Cu-67) to ensure expanded and reliable supply of this promising radioisotope for the treatment of patients with cancer. Explore what lies ahead for radioisotope manufacturing in Beloit, Wisconsin.

ISOTOPE PROCESSING FACILITY

Our Isotope Processing facility features a chemical processing line, analytical testing and metallurgy laboratories, as well as radioactive storage. Regular production runs of radiochemical grade (RCG) Copper-67 (Cu-67) occur in this facility. Currently, the building is undergoing a significant infrastructure project, which includes the addition of new processing lines and product hot cells. Additionally, work is underway to retrofit previously installed hot cells that were dedicated to the production of other isotopes but will now be used to help us maximize our output of Cu-67. These upgrades are part of our plan to upscale processes and position ourselves for large-scale cGMP commercial production. Furthermore, this facility houses a cGMP-compliant, final dose product CDMO suite.

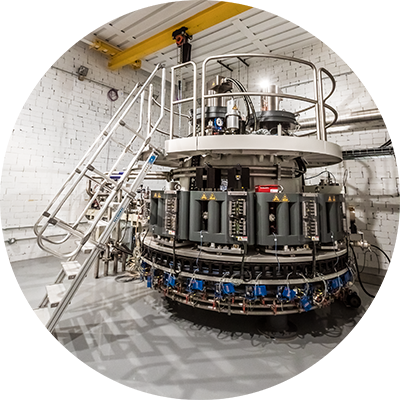

COPPER-67 ACCELERATOR PRODUCTION FACILITY

We are currently irradiating and investing in the expansion of our groundbreaking technology to produce Copper-67 (Cu-67) from Zinc-68 (Zn-68) using electron beam accelerators. During the initial construction phase, our team had the foresight to prepare the areas immediately adjacent to the production facility, allowing for easier expansion. NorthStar’s unique and proprietary electron accelerator production facility and processes are designed to optimize efficiency throughout the production cycle, providing us with the flexibility to produce batches of various sizes based on market demand.

ACTINIUM-225 PRODUCTION FACILITY

We continue our investment in groundbreaking technology to produce non-carrier added Actinium-225 (n.c.a. Ac-225) from Radium-226 (Ra-226) using our electron beam accelerators. There are several technologies used to produce Ac-225 but none that can independently scale to meet commercial quantities. NorthStar’s method is capable of meeting customer demand. Our stand-alone facility, currently under construction, will fully house our dedicated electron beam accelerator, chemical processing line and all analytical laboratory capabilities.

CDMO/CMO FACILITY

NorthStar’s Radiopharmaceutical CDMO/CMO unit offers customized services and expertise to accelerate biopharmaceutical companies’ development and commercialization programs. The NorthStar CDMO is the first and only U.S. facility providing commercial-scale, multi-radioisotope production and radiopharmaceutical development all on the same campus. With a 52,000 sq. ft. footprint, it sets new industry standards, serving the growing therapeutic and diagnostic radiopharmaceuticals market. Our facility effectively supports the entire product lifecycle, cGMP manufacturing suites, one EU compliant manufacturing suite and radiation safety programs to ensure high-quality and safe practices.